Made in Portugal

Your old Clepto shirts just don't break? And even though you wash colored clothes together, black and white, the seagull sails bravely against fading like it does against a force seven wind from the northwest? The reason for the long-lasting quality can be found in a country at the very tip of Europe that has been producing high-quality textiles for even longer than Cleptomanicx - Portugal.

Made in Portugal

Your old Clepto shirts just don't break? And even though for you, washing colored clothes also means washing black and white together, the seagull sails bravely against fading like it does against seven force northwest winds? The reason for the long-lasting quality can be found in a country at the very tip of Europe that has been producing high-quality textiles for even longer than Cleptomanicx — Portugal.

Fair working conditions

Around two thirds of our products are manufactured in Braga. Because the name of the city probably means as little to you as it did to us 20 years ago, we want to introduce you to the rugged beauty of northern Portugal.

Because the high quality of our products is just as important to us as the conditions under which they are produced, we decided early on to work with permanent partners. So that you are not the only one who associates the seagull with the good life, ensuring fair working conditions for our partners on the Atlantic and sustainable production processes are essential for us. To find out more about how we work, you should definitely get to know Joao, Marina and Manuel, three employees of the companies that welcomed us so warmly in the north of Portugal.

Nobody wakes up and says to themselves: "Today I really want to pollute the environment again!" But environmental protection doesn't happen on its own. Through close contact with our producers in Portugal, we can influence the chemicals used in production. We receive a list of the chemicals used in the entire production process from all the producers involved. This means we exceed the prescribed REACH standard and can identify and replace questionable chemicals. In the Restricted Substances List (RSL), we go one step further. If a substance does not meet our conditions, it is excluded and an environmentally friendly substitute is sought and found.

Production in Europe

Substances that are highly toxic to humans, have genetic effects, are carcinogenic, affect reproductive function, are toxic to aquatic organisms, have long-term harmful effects or are dangerous to the ozone layer are excluded.

A big advantage of our production in Europe is the proximity to the production facilities and their operators. Unlike production in the Far East, here we have the opportunity for frequent direct exchange with our partners. For 20 years, Cleptomanicx has been producing its shirts, tops and hoodies in collaboration with the Torres family. They monitor production on site and ensure that all production steps run smoothly. They are also excellent hosts who have always surprised us with a bottle of port wine during our visits... 55% of our goods are produced in Barcelos, near the old university town of Braga. We know all of the suppliers personally and know which chemicals are used and under which conditions they work.

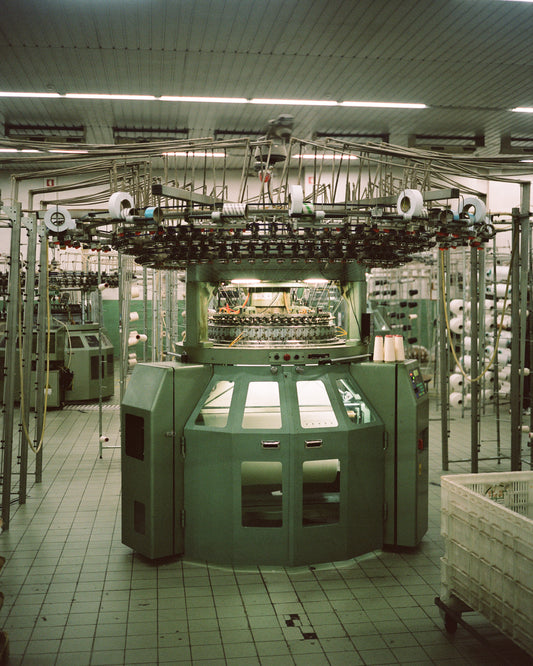

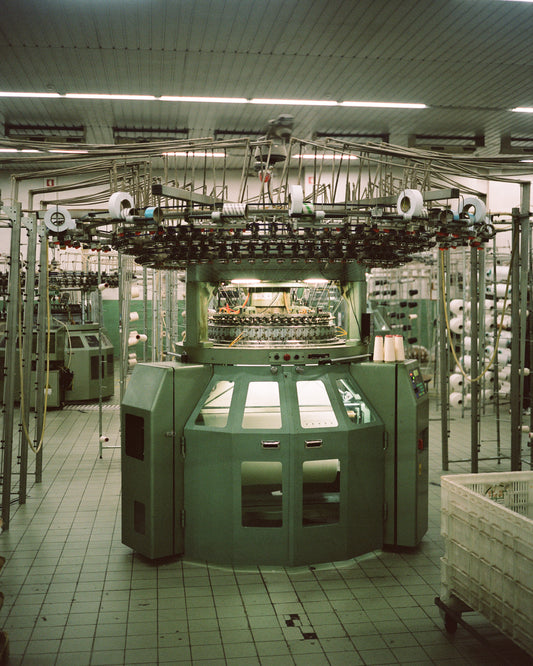

The industrial infrastructure of the town allows us to keep delivery routes short during ongoing production. All production steps from the organic cotton imported as raw yarn take place within a radius of 20 kilometers: fabric production, dyeing, cutting, sewing, printing, embroidery to sewing in the size labels and tacking on the price tags. The seagull's nest is prepared by the fabric supplier Fervi. He has been working with the Torres family for 20 years and makes our fabrics for hoodies and shirts from undyed yarn. The raw yarn is purchased by representatives of the Fervi company in Turkey, Uzbekistan, Pakistan and India. At Fervi, huge vacuum cleaner tubes ensure that the cotton dust that arises during production, which is generated when the yarn rubs in the machines, is regularly removed from the air. This is a standard precaution in fabric factories and is carried out particularly carefully here. Yarn scraps that arise during production can be processed into insulation and plastering material.

Environmentally friendly

All of life is chemistry. These were the wise words of our teacher. In the case of Manuel and Bernardino Costa, this sentence is absolutely true, because they have been making use of a simple chemical reaction for a long time.

In their factory, 40 employees give the raw yarn the right look using reactive dyeing - now look at the notes from class again! All dyes and aids used meet strict ecological standards and are harmless to the environment. The cutting of the pattern pieces takes place in the Torres family's in-house cutting department. Four to five people work here at the electrically operated cutting tables. The seagull is printed on the printer using a screen printing process. To make our star shine even on dark backgrounds, we use the gentlest possible printing pastes. On light fabrics, white viscose emulsions mixed with ink and water are sufficient. All of the materials meet strict ecological requirements.

But who makes a shirt out of the different pieces of fabric? Two women-run sewing factories in the immediate vicinity of Braga put the sum of the individual pieces together. This is not magic, but honest work, which we pay fairly, like all other production steps. Each of the ten seamstresses receives a fixed monthly salary that is above the wage level in the region and is paid 14 times a year. When producing new Cleptomanicx styles, many things are of course not only finished at the last minute, which is why the workers' overtime is also paid. These fair working conditions enable them to devote themselves to their task with great dedication, which is ultimately reflected in the high quality of our products. After this last step, the fresh pieces sail back from the Atlantic to the North Sea and are finally with you - ready to board!